ELTRIX Plant Performance Management

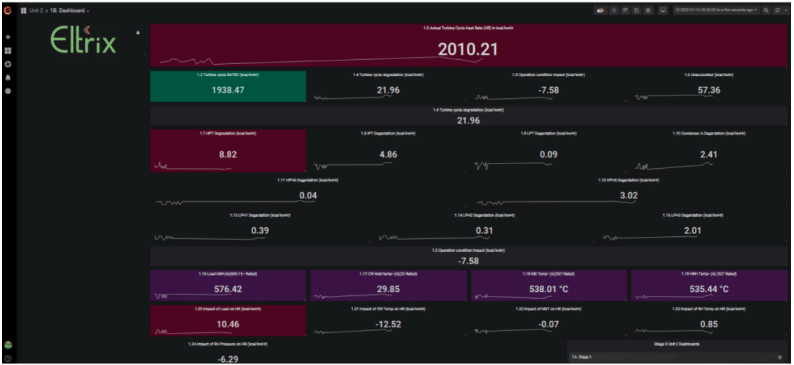

Eltrix Plant Performance Management (PPM) software provides power plant operators with real-time plant performance and breaks down causes for performance deterioration and improvement suggestions.

Eltrix Plant Performance Management (PPM) software provides power plant operators with real-time plant performance and breaks down causes for performance deterioration and improvement suggestions.

ELTRIX Plant Performance Management (PPM) software module enables power plant operators to understand the plant performance. Eltrix software breaks down the causes of Heat Rate deviation into Operating condition (load, cooling water temp, etc) and Equipment Degradation (turbines, condenser, heater).

Eltrix uses state of the art AI tools like neural network and advance thermodynamic model and segregates the cause of Heat Rate deviation into two buckets viz. equipment degradation and operating condition deviation. It analyses the boiler, turbine, condenser, heater, and pumps according to ASME/PTC equations and displays the heat rate deviation online and offline. It takes data from plant DCS through OPC for the calculation.

Eltrix analyses the gap in heat rate by segregating it into two buckets viz. equipment degradation and operating condition deviation.The benefits of separating the Heat Rate (HR) deviation into the two buckets are: